Today's HoursThursday 8:30AM - 5:00PM

Today's HoursThursday 8:30AM - 5:00PM

| Monday | 8:30AM - 5:00PM |

| Tuesday | 8:30AM - 5:00PM |

| Wednesday | 8:30AM - 5:00PM |

| Thursday | 8:30AM - 5:00PM |

| friday | 8:30AM - 5:00PM |

| Saturday | 8:30AM - noon |

| Sunday | Closed |

ID # 34914830

Krone Front-mounted disc mowers EasyCut F

Call for Price

Overview

Specifications

safecut

smartcut

easycut f

the cutterbar

brochure pdf

Videos

Documents

|

Model

Front-mounted disc mowers EasyCut F

Category Name

Agriculture

Year

2023

Sale Type

New

Manufacturer

Krone

SafeCut

|

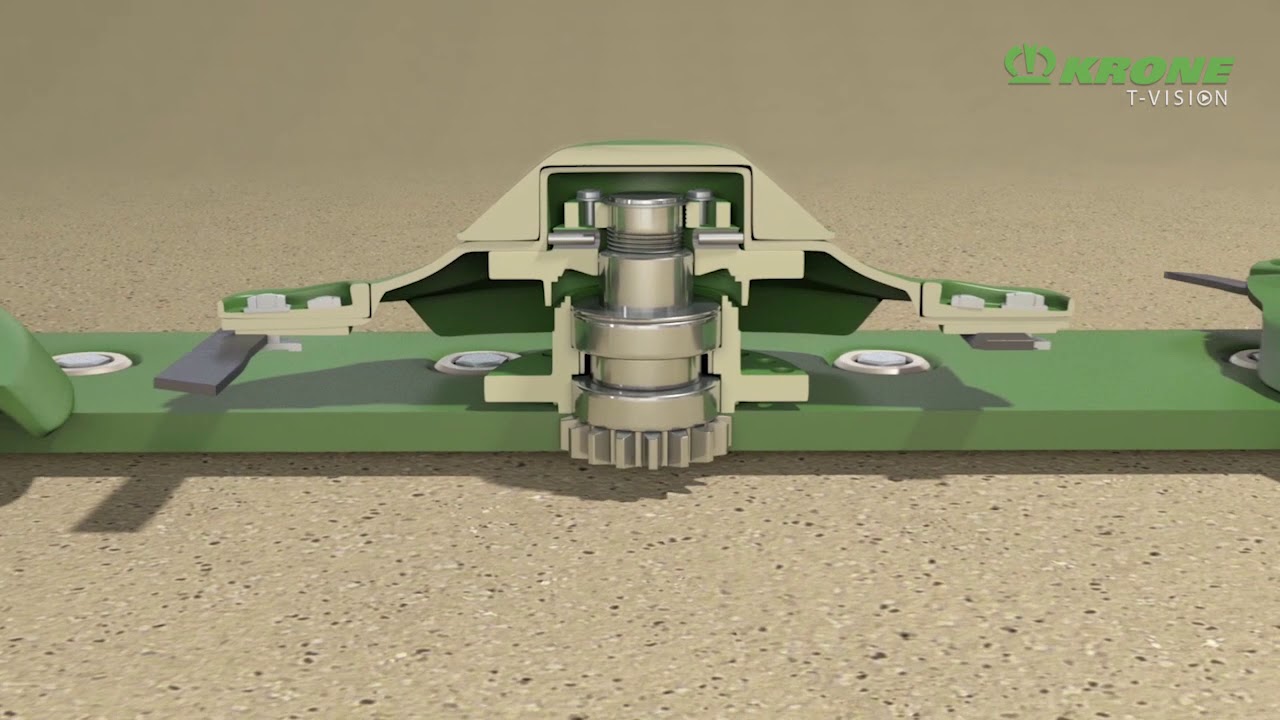

| Foreign objects can cause great damage and costly repairs. Not so if the KRONE SafeCut is in place, which allows the discs to move away from obstacles for maximum productivity and comfort. Our DLG award winning disc protection system is a base specification on all EasyCut models. |

An ideal system: As the discs are spinning, they place no load on the roll pins, because the bearings are tensioned by a nut and two clamping screws. As a result, the roll pins do not suffer from material fatigue and even after many hours of operation they will break only at their inbuilt load level. |

Peace of mind: Instead of transferring the full shockload to the spur gears, the roll pin in the sprocket driveshaft breaks when there is a momentary overload. The pinion shaft continues spinning, jacking up the disc in question and the disc moves out of the risk zone and the orbit of the neighbouring discs. This way SafeCut prevents damage to the spur gears and the neighbouring discs. Replacing the roll pin takes a few minutes and is not very costly. |

SmartCut

|

| The wedge-shaped cutterbar adjusts through a large setting range to cut short stubble in meadows and pastures and longer stubble in longstemmed field crops. EasyCut cuts blockage-free and clean. Benefitting from massive double spur gear bearings that are spaced at large gaps, the cutterbars are heavy-duty and hardwearing. |

Forget about stripes With some discs turning in pairs towards each other and others away from each other, it was necessary to redesign the degree of blade overlap to ensure cleanest cuts. Therefore we increased the overlap between those discs that turn outwards – a modification that leads to stripeless cuts in light and young material. Vice versa, a larger gap between the blades that turn towards each other encourages the smooth flow of large masses to the rear. |

Windrowing: Spinning inwards, the discs feed the material to the middle of the machine to avoid tractor wheels running over the cut crops. With discs spinning in the A sense of rotation, EasyCut R 280 and R 320 form one swath. Whereas EasyCut R 360 forms two swaths with its discs also spinning in the A sense of rotation. |

Spreading across the full width: The EasyCut models, with discs spinning in the ‘B’ sense of rotation, spread the material across the machine width. All discs spin in pairs. Material that is spread across the full machine width will dry faster and more evenly. |

F 280 • F 320 • F 360

|

| The KRONE EasyCut F 280 and F 320 stand out for their massive top hats which mount behind the discs on either end of the cutterbar. Driven from within the cutterbar, they provide a consistent flow of crop to the centre of the machine so that the tractor wheels will not run on the fluffy swath and the harvester will pick up the material without losses. |

Powered top hats: With all discs turning towards the middle on the EasyCut F 280 and F 320 models, they automatically feed the cut material to the middle whilst the powered top hats control the fl ow to the rear. It is down to their high feed capacity that the material is presented in uniform windrows, even on the slope. |

Narrow windrows: EasyCut F 320 can take taller top hats which are bolted to the smaller standard-fit hats on the inside. The taller hats reduce the windrow width by another 40 cm (1'4") for narrow tractors to straddle them. |

Want wider windrows? Our EasyCut F 320 models feature small inner hats along with the tall hats – an ideal configuration when matching up with a wide spreading rear mower. |

A perfect system: EasyCut F 280 and F 320 are mowers that adapt to any type of ground contours – in and across the direction of travel. The pushed design allows for plenty of up and down travel – the ideal design for rough terrain. In addition, the compact build offers an excellent overview in the field and an excellent transport stability for safe travel on public roads. As it mounts close to the tractor, the linkage travels through a smaller angle and less strain is put on the driveshaft. |

A good follower Pivoting through a large 40 cm (1'3'') range, these disc mowers follow any ground contour, produce clean forage and leave a healthy sward. |

Protection all-round: Rubber strips grab the edge of the side and front guards to serve as bumpers and reduce collision damage and preserve the machine’s value. |

280 M • F 320 M • F 360 M

|

| Mountain farming is a particular challenge to man and machine. The front-mounted 2.73 m (8’11") EasyCut F 280 M, the 3.16 m (10'4") F 320 M, and the 3.60 m (11'9") F 360 M disc mowers are the ideal machines to take on the challenge, boasting a compact design, a centre of gravity close to the tractor, perfect cuts on steep slopes and good attachment options to light-weight and very compact mountain tractors. The EasyCut 360 M model is the ideal machine for huge track widths and offers generous overlap in combination with rear mowers. |

Perfect ground hugging: The pushing suspension design provides a generous vertical travel and combines with long skids and an optional telescoping top link to provide optimum ground hugging in every way. Mounted extremely close to the tractor, the mower travels very little when gliding over undulations. The design reduces wear on the driveshaft and enhances operator overview. |

Generous up and down travel: With each end pivoting through 30 cm (1'), EasyCut F 280 M and F 320 M guarantee cleanest cuts in undulating terrain and a well protected sward. |

Centre-of-gravity suspension: The front mowers EasyCut F 280 M, F 320 M and F 360 M are not suspended in their mid-point but in their centre of gravity – a design that distributes the pressure uniformly across the entire work width and leads to cleanest cuts. |

Compact transport position: The guard ends on EasyCut F 280 M and F 320 M front fold back to bring the transport width down to 3.00 m (9'10''). They can also fold hydraulically as an option. EasyCut 360 M has transport width of 3.45 m (11'4"). |

F 320 CV • F 320 CR Push/Pull

F 360 CV • F 360 CR Push/Pull

Brochure PDF

| Name | Link |

| Brochure PDF | Download |

Documents

Model

Front-mounted disc mowers EasyCut F

Category Name

Agriculture

Year

2023

Sale Type

New

Manufacturer

Krone

Quantity

0

Tel:

Tel:  22 Callaghan Road, Lindsay, ON K9V 4R4

22 Callaghan Road, Lindsay, ON K9V 4R4