Today's HoursThursday 8:30AM - 5:00PM

Today's HoursThursday 8:30AM - 5:00PM

| Monday | 8:30AM - 5:00PM |

| Tuesday | 8:30AM - 5:00PM |

| Wednesday | 8:30AM - 5:00PM |

| Thursday | 8:30AM - 5:00PM |

| friday | 8:30AM - 5:00PM |

| Saturday | 8:30AM - noon |

| Sunday | Closed |

Krone

ID # 34914828

Krone Rear-mounted disc mowers ActiveMow

Call for Price

Overview

Specifications

smartcut

the cutterbar

the working formula

optimum ground pressure

perfect in every detail

windrowing or spreading

practical and well-designed

brochure download

Videos

Documents

|

Model

Rear-mounted disc mowers ActiveMow

Category Name

Agriculture

Sale Type

New

Manufacturer

Krone

SmartCut

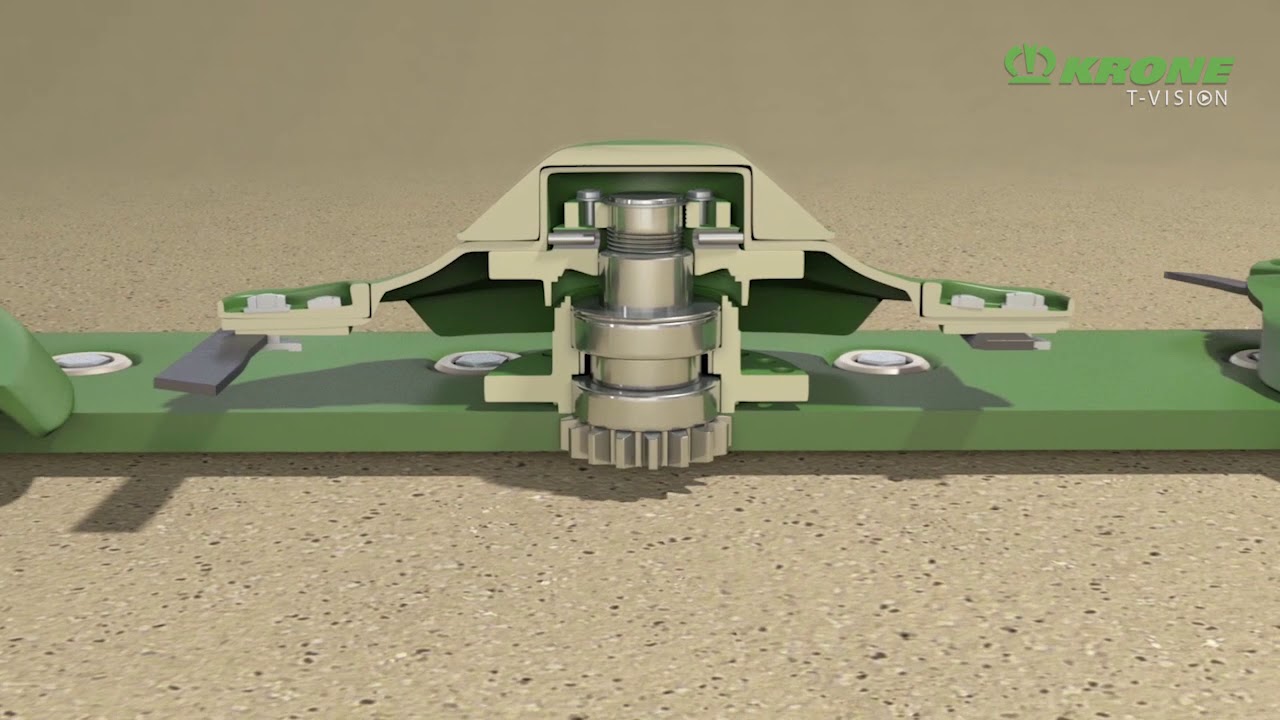

SmartCut: With some discs turning in pairs towards each other and others away from each other, it was necessary to redesign the degree of blade overlap to ensure cleanest cuts. Therefore we increased the overlap between those discs that turn outwards. This way you achieve stripeless cuts in light and young material. The large spacing between the blades spinning away from each other encourages a smooth flow in high volumes of crop. |

Damage protection The rounded wear plates between the skids protect the cutterbar from damage. A special contour on the underside prevents any material from building up here, ensuring an undisturbed crop flow to the rear. |

The Working Formula

|

The formula that works for you Tractor attachment with three-point headstock Large travel range for superior performance in mountainous terrain Direct and frictional driveline ensures no power is lost Working a full width by refitting pin on the link arms |

Heavy-duty: The three-point headstock is sturdy and robust. There is also a holder where you can store the driveshaft after removing the machine from the tractor. |

Constant-velocity and high-torque driveline: The drive power flows down a frictional driveline made up of pto shafts and gearwheels, a system that warrants an efficient transmission of the power from the tractor all the way down to the discs – even in the most difficult conditions. |

Optimum Ground Pressure

|

Optimum ground pressure from 2.05 m to 3,61 m

|

One coil spring: The low dead weight of the ActiveMow R 200 model allows using one suspension spring that offers infinitely variable adjustment. |

Two coil springs The ActiveMow R 240 model has two suspension springs which are adjusted without tools. The top spring is adjusted on a spindle whereas the smaller spring is adjusted by refitting a pin. |

Three suspension springs: ActiveMow R 280, R 320 and R 360 have three adjustable suspension springs – two large top springs and one smaller spring arranged underneath. |

Perfect In Every Detail

|

| Quick-change blades, low wear costs and perfectly aligned discs for stripeless cuts are only some of the benefits ActiveMow users buy. |

Quick-change blades are a must for many farmers and contractors. The blades are quick and easy to reverse or replace in situ. |

On-board storage box: The on-board drawer holds spare blades and keeps the cab clutter-free. |

Easily accessible: The deck folds up to give easy access to all components for cleaning and convenient blade replacement. |

Windrowing Or Spreading

One windrow or two windrows: The eccentric bearings are positioned in such a way that the discs turn inwards to the middle of the machine. On the ActiveMow R 200, R 240, R 280 and R 320 models the discs spin in the sense of rotation that is considered as ‘A’, producing one single windrow. By comparison, spinning in the ‘A’ sense of rotation, the ActiveMow R 360 model delivers two windrows. |

Advantages of windrowing Windrowing offers a number of benefits on wet and boggy ground, because the material is not pressed into the ground by the tractor wheels and can be collected or conditioned without losses. |

Spreading across the full width: The ActiveMow models that have their discs spin in pairs in the sense of rotation considered as ‘B’ spread the material across the cutting width. |

Advantages of spreading: Material that is not windrowed but spread across the full working width dries faster and more uniformly, because a larger surface area is exposed to the sun and wind. |

Practical And Well-designed

Stands are available as an option to store the machine either in work or transport position – saving valuable space in the machine shed. The top guard folds automatically when EasyCut R 360 moves into transport or park position thereby reducing the machine’s height (left). |

Easy attachment and removal: Attachment and removal is very easy once the handle has been released to decompress the spring. This feature is available on the ActiveMow R 240, R 280, R 320 and R 360 models. There is no need to unhook the spring. |

Safe transport: The ActiveMow mower swings up into a 100° position behind the tractor. Reducing the weight on the right rear wheel, this position results in smoother travel and a clear view to the rear through the mirror. |

Brochure Download

| Name | Link |

| Brochure Download | Download |

Documents

Model

Rear-mounted disc mowers ActiveMow

Category Name

Agriculture

Sale Type

New

Manufacturer

Krone

Quantity

0

Tel:

Tel:  22 Callaghan Road, Lindsay, ON K9V 4R4

22 Callaghan Road, Lindsay, ON K9V 4R4