Today's HoursThursday 8:30AM - 5:00PM

Today's HoursThursday 8:30AM - 5:00PM

| Monday | 8:30AM - 5:00PM |

| Tuesday | 8:30AM - 5:00PM |

| Wednesday | 8:30AM - 5:00PM |

| Thursday | 8:30AM - 5:00PM |

| friday | 8:30AM - 5:00PM |

| Saturday | 8:30AM - noon |

| Sunday | Closed |

New Equipment

Krone BiG M 420

High-Performance Mower Conditioner BiG M 420 |

|

| Powerful monster tackles every job: KRONE proudly presents BiG M 420 – a versatile specialist that takes care of all your mowing applications. BiG M 420 is the machine that gears you up for every task. Just look at its high-output CV conditioner or CRi roller conditioner or take the spreading or swath merging options. Cutting at an enormous work width of up to 9.7 metres (31'10") and offering tremendous power reserves while distributing the weight uniformly, BiG M 420 produces clean and high-quality forage without affecting the re-growth of crops – in any condition and any field around the world. One does it all: BiG M 420 delivers total efficiency – even in small fields. The machine scores perfect on handling and fast travelling between fields. Opening up small and awkward fields is as easy as it can get – thanks to the machine‘s great maneuverability and the option of using the mowers separately. This machine is up and working while others are still preparing for work. |

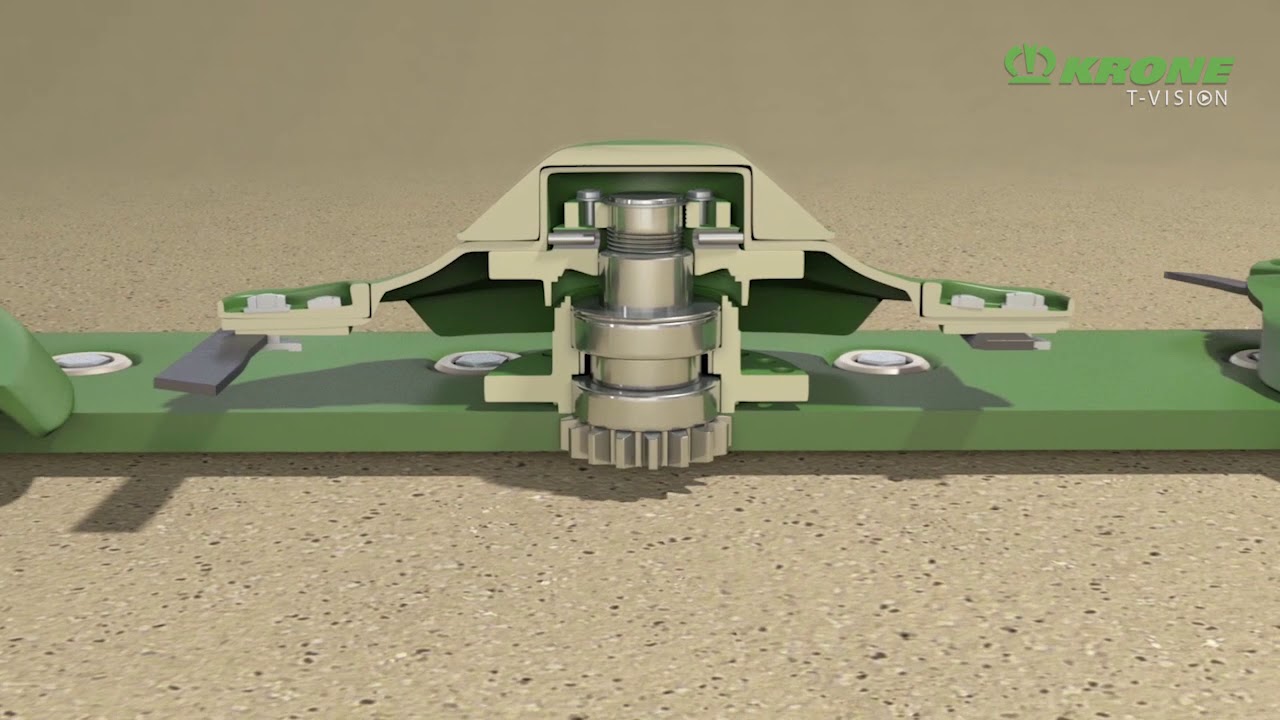

The EasyCut cutterbar

|

|

Efficiency and safety

The three disc mowers on BiG M 420 are well-proven technology, which is sourced from our EasyCut mower range. The fully welded and heavy-duty cutterbar with satellite driveline provides maximum stability while the power flows through the rear gearbox and down massive and quiet-running spur gears to drive the satellite gears and the discs. The discs mount in a very forward position and guarantee clean cuts thanks to perfect overlapping. All BiG M 420 models feature the standard SafeCut protection system, which gives the best possible protection when the cutterbar hits a foreign object. |

SafeCut – a KRONE exclusive: Each disc on a KRONE cutterbar is individually protected. Rather than transferring the shock load of the impact to the cutterbar, the system transfers the load to a roll pin, which breaks as a result of the impact. Then the disc moves 15 mm (0.6") up on its threaded drive pin and out of the risk zone and away from the neighboring discs. |

Maximum operator comfort

|

‘Silent Space ‘– The name says it all

‘Silent Space ‘– The name says it all

A generous and quiet space – that’s the new KRONE cab which caters for all operator needs during those long working days. Mounted on hydro bearings, this cab o ers a maximum of operator comfort and an optimum work environment no matter how harsh the conditions. Designed to ergonomic standards, the interior of this cab o ers plenty of space and has a standard passenger seat, climate control and an electric cool box. Logically arranged control panels provide full overview and control of all machine functions. |

Comfy seating – excellent vision Generous glazing and slim posts make for a perfectly clear view of the mowers. Also, H3 work lights (optional LEDs) are a boon at night. Another option is the ‘Activo’ seat, which brings operator comfort to another dimension, offering active climate control with integral seat heating, low-frequency air suspension and automatic adjustment to the operator’s weight. Comfy seating – excellent vision Generous glazing and slim posts make for a perfectly clear view of the mowers. Also, H3 work lights (optional LEDs) are a boon at night. Another option is the ‘Activo’ seat, which brings operator comfort to another dimension, offering active climate control with integral seat heating, low-frequency air suspension and automatic adjustment to the operator’s weight. |

EasyTouch Display: All major machine information is instantly available on the EasyTouch high-resolution color display screen. Enter the sub-menus quickly and easily from the keys next to the display screen. EasyTouch Display: All major machine information is instantly available on the EasyTouch high-resolution color display screen. Enter the sub-menus quickly and easily from the keys next to the display screen. |

Functional: The switches that control the lights, the work lights, the windshield wiper as well as heating and air conditioning are located in the roof right in front of the operator. The ‘Follow Me Home Function’ delays light deactivation of two work lights for 180 seconds as the operator leaves the cab. Functional: The switches that control the lights, the work lights, the windshield wiper as well as heating and air conditioning are located in the roof right in front of the operator. The ‘Follow Me Home Function’ delays light deactivation of two work lights for 180 seconds as the operator leaves the cab. |

|

Easy operation

|

The Engine

|

|

Powerful, Reliable Engine Electronics Increased feature and connection commonality improve the customer experience and increase quality and reliability. Sealed-over-foam wiring harness adds to reliability - even in the most demanding applications. |

|

Next Generation Fuel System Advanced MEUI-C injectors handle increased injection pressures and more precise fuel rates. These durable injectors enhance responsiveness while controlling soot. |

|

Innovative Air Management A simple, efficient turbocharger delivers variable turbo boost, reliable performance and long service life in the most demanding applications. |

|

Cat® NOx Reduction System The Cat® NOx Reduction System captures and cools a small quantity of exhaust gas and sends it back into the combustion chamber where it drives down combustion temperatures and reduces NOx emissions. The Cat® NOx Reduction System is designed to be the most reliable system of its type. |

KRONE exclusives

|

Carefully designed for efficiency

The innovative KRONE BiG M 420 driveline allows operators to achieve work rates of more than 15 hectares (37 acres) per hour. After all, short and direct drivelines offer the best efficiency. From the axial engine, the power flows directly to the transfer box, which in turn splits the flow and transfers it to the individual mowers. Extra strong 4-groove poly V-belts transmit the power directly to the side mowers, which suspend from massive coil springs in their center of gravity. The design gives optimum floating and the tension of the coil springs is conveniently adjusted from the cab. The pushed front mower benefits from large travel to adapt perfectly to all ground contours. |

| Direct drivelines: BiG M 420 uses short and direct drivelines to transfer the engine power to the mowers. The transfer gearbox is positioned right in front of the axial-mount engine and sends the engine power to the individual mowers – a driveline that eliminates any losses and sends the power where it is required. |

Merges 9.7 metres (31'10") into one swath

|

|

Merging more than 9 metres (29'6") of crop into one swath

This optional merging system groups all passes into one – cutting, conditioning and windrowing. Integral augers in the two side mowers feed the conditioned material directly to the swath left by the front mower. This optional system offers extraordinary benefits in harvest chains that do without tedding and swathing. The system produces excellently clean swaths in grass, alfalfa and wet silage, which are easily picked up by the following harvester. |

Swathing: When the hoods are closed, the augers transfer the conditioned material to the center of the machine and place it into one single swath. The system leads to a significant reduction in crop contamination. |

Wide spreading on one side: Open the hood on one mower only and BiG M swathes the material to one side. In one up and down operation, the machine is then cutting at widths of up to 19.4 metres (63'8") and swathes the material down to a width of only 12 metres (39'4"). These swaths are easily gathered by a Swadro 1400. |

Spreading across the full width: When the hoods are open, the machine throws the conditioned material over the rotating augers and spreads it across the working width for uniform and rapid drying. This eliminates the tedding pass. |

Safe and convenient

|

Viable and efficient: Speed is the crucial factor in increased efficiency. In the field, our SP BiG M 420 works at a rate of more than 15 ha/h (37 acres/hr) whereas it travels at 40 km/h (25 mph) between fields. Naturally, the machine offers such features as cruise control and headland management system, which help reduce operator stress and allow the operator to concentrate on the actual harvesting operation. Viable and efficient: Speed is the crucial factor in increased efficiency. In the field, our SP BiG M 420 works at a rate of more than 15 ha/h (37 acres/hr) whereas it travels at 40 km/h (25 mph) between fields. Naturally, the machine offers such features as cruise control and headland management system, which help reduce operator stress and allow the operator to concentrate on the actual harvesting operation. |

Three conditioner versions

|

|

The conditioner versions

Quality is as important as efficiency. To ensure the crop dries rapidly and uniformly, it is recommended to use a conditioner, which rubs off the natural wax skin for the moisture to evaporate faster. KRONE offers a choice of three conditioner versions. The CV conditioner features V-tines made from steel and offers two speeds (700 rpm and 1,000 rpm) whereas the CRi roller conditioner comes either with two profiled polyurethane rollers or with steel rollers to treat vulnerable and broad-leaved crops, such as legumes. |

The CV conditioner for 9.7 m (31'10") working widths: The V-type steel tines on the 66 cm (2'2") diameter rotor feed the crop past a baffle plate to provide intensive conditioning. The operator sets the rotor speed conveniently on the gearbox to 700 rpm or 1,000 rpm and adjusts the baffle plate steplessly. |

Tel:

Tel:  22 Callaghan Road, Lindsay, ON K9V 4R4

22 Callaghan Road, Lindsay, ON K9V 4R4