Today's HoursThursday 8:30AM - 5:00PM

Today's HoursThursday 8:30AM - 5:00PM

| Monday | 8:30AM - 5:00PM |

| Tuesday | 8:30AM - 5:00PM |

| Wednesday | 8:30AM - 5:00PM |

| Thursday | 8:30AM - 5:00PM |

| friday | 8:30AM - 5:00PM |

| Saturday | 8:30AM - noon |

| Sunday | Closed |

New Equipment

Krone Mower Combinations EasyCut B

|

|

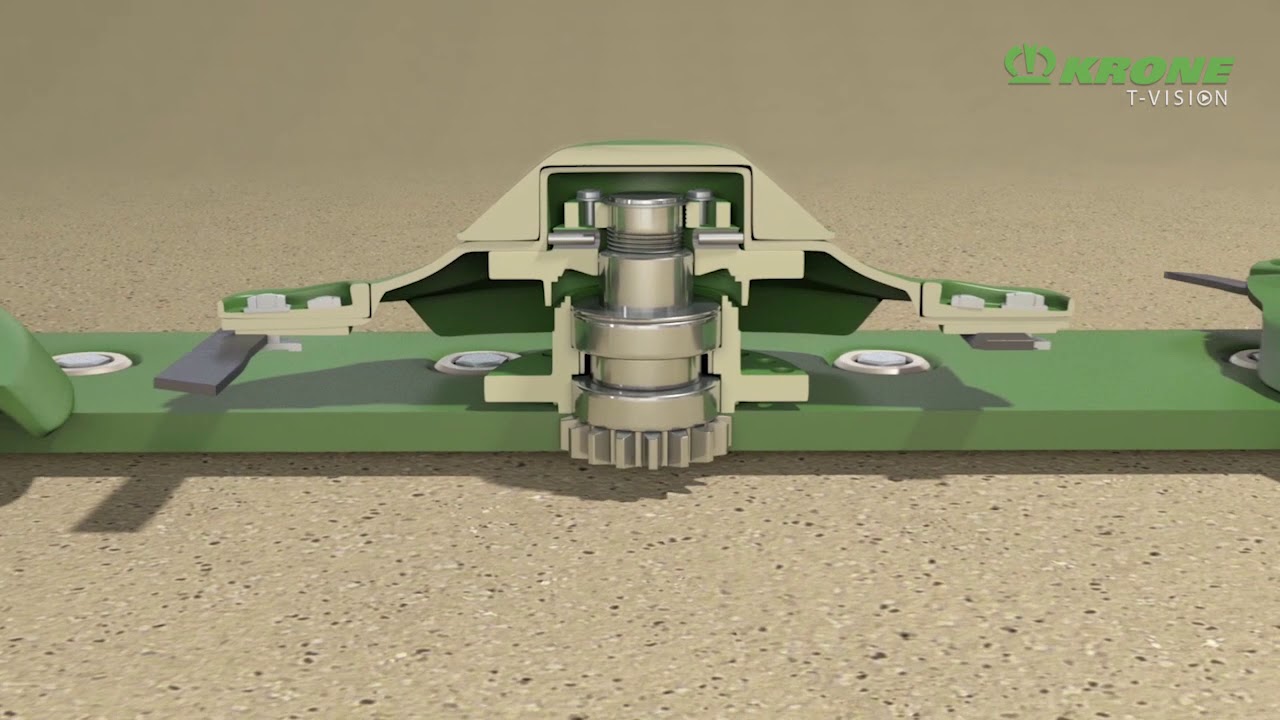

| Colliding discs may cause damage and involve costly repairs. KRONE SafeCut offers a maximum of protection and peace of mind. The award winning system on all EasyCut models offers a unique level of protection and operator comfort. SafeCut is a base specification feature on all EasyCut F and R models. |

Each disc on the mower has its own individual impact protection. When the blade hits an obstacle the shockload is transferred to a roll pin which breaks. As a result, the disc automatically threads 15 mm up on the drive shaft. |

Peace of mind: Instead of transferring the full shockload to the spur gears, the roll pin in the sprocket driveshaft breaks when there is a momentary overload. The pinion shaft continues spinning, jacking up the disc in question and the disc moves out of the risk zone and the orbit of the neighbouring discs. This way SafeCut prevents damage to the spur gears and the neighbouring discs. Replacing the roll pin takes a few minutes and is not very costly. |

Forget about stripes: With some discs turning in pairs towards each other and others away from each other, it was necessary to redesign the degree of blade overlap to get cleanest cuts. Therefore we increased the overlap between those discs that turn outwards – a modification that leads to stripeless cuts in light and young material. Vice versa, a larger gap between the blades that turn towards each other encourages the smooth flow of large masses to the rear. |

The original: The KRONE developed satellite driveline comprises massive spur gears with up to 66 teeth which transfer the power all the way down to the very last disc. Revolving at lower speeds, the large-diameter gears always have a number of teeth in mesh at any one time, giving quiet running, ultimate efficiency and maximum longevity. With each of the auxiliary gears driving just one disc, it is exposed to only minimum mechanical strain. |

The wedge-shaped cutterbar offers many height setting options. The spur gears run in massive double bearings, allowing the cutterbar to handle extremely high loads. |

|

EasyCut B 950 Collect

|

|

The EasyCut B 950 Collect is a very compact combination that has merger augers but no conditioners. The massive augers merge large volumes of crop such as green rye into a uniform and clean swath. Use the mouse or your finger to drag the image and view the EasyCut B 950 Collect from every angle in this 360° video. |

The sturdy 45 cm diameter cross augers are powered by a right-angle gearbox and revolve at a consistent speed of 750rpm, giving maximum efficiency and productivity. Arranged closely behind the cutterbars, these augers feed large volumes of crop in a consistent flow from the mowers to the middle of the combination, forming a tidy and uniform swath that is cleanly gathered by the following harvesters. |

The decks behind the augers open and close hydrauli-cally for convenient selection of one of the three swathing modes from the cab: swathing, independent swathing or no swathing. |

- Variable, up to 10.00 m work widths on EasyCut B 1000

- Weight-optimized headstock reduces rear axle weight and ground pressure.

- Adjustable non-stop break-back system is a standard feature

- SmartCut and SafeCut ensure perfect cuts and maximum uptime

- Hydraulic suspension is as a standard feature

The EasyCut B 870 and B 1000 are two high-capacity mower combinations. They feature leading edge technology and a new styling plus a weight-optimised headstock with hydraulic suspension that helps protect the sward and also attaches to smaller tractors.

The EasyCut B 870 and B 1000 are two high-capacity mower combinations. They feature leading edge technology and a new styling plus a weight-optimised headstock with hydraulic suspension that helps protect the sward and also attaches to smaller tractors.

|

EasyCut B 870 CV · B 870 CR

|

| EasyCut B 870 CV and CR utilize the tractor to the full and save time and costs. The versatile model is the EasyCut B 870. Featuring conditioners and extra wide merger belts, this machine enables you to cut, condition and spread or swath the material in one single pass.  |

A KRONE exclusive! The patented balancer arm allows adjusting the spring tension on both rear mowers to maintain a consistent ground pressure, warranting highest quality cuts, clean forage, light pulling and effective protection of the valuable sward. |

|

EasyCut B 1000 CV · B 1000 CR

|

The EasyCut B 1000 CV and EasyCut B 1000 CR stand out for a huge 10.10 m work width and their powerful CV or CR conditioners. Another high-profile feature is the world-first Combi Float – the automatic and hydro-pneumatic control system. The EasyCut B 1000 CV and EasyCut B 1000 CR stand out for a huge 10.10 m work width and their powerful CV or CR conditioners. Another high-profile feature is the world-first Combi Float – the automatic and hydro-pneumatic control system. |

|

|

|

The automatic Combi Float suspension control offers unique advantages: The automatic Combi Float suspension control offers unique advantages:

|

Combi Float – only from KRONE: The speciality of the system is the fact that it uses extra spools and the circuit of the single-acting coupler with free return line to maintain the pressure inside the reservoirs of the hydro-pneumatic system. The advantage of this system is that it maintains a uniform suspension of both mowers in undulating terrain and when working at various work widths. |

|

|

The KRONE mower combinations offer professional farmers and contractors the specification and comfort they need: a large work width, an enormous efficiency and compact build, as well as low tractor input, ease of operation and excellent handling – all being true benchmark features for a mower in this class.  |

|

Minimum space: Folded into transport position and safely propped by sturdy stands, the 2.95 m wide EasyCut B 750, B 890 and B 970 models require about 3.70 m to 4.00 m in height. In transport, these machines won’t exceed the maximum height of 4 m and yet give a generous 25 cm ground clearance.  |

|

The KRONE CR roller conditioners

|

Leafy crops like Lucerne or clovers require a different type of conditioning than crops that are predominantly grass. The CR roller conditioners give particularly gentle treatment, leaving the delicate leaves intact which are so rich in protein and safeguarding the value of the feed. Spreading the crop will speed up wilting. Leafy crops like Lucerne or clovers require a different type of conditioning than crops that are predominantly grass. The CR roller conditioners give particularly gentle treatment, leaving the delicate leaves intact which are so rich in protein and safeguarding the value of the feed. Spreading the crop will speed up wilting. |

|

The KRONE CV tine conditioner

|

| Efficiency is one parameter in hay and forage harvesting, quality is another. The high-performance KRONE CV conditioner with V-shaped steel tines spreads the crop at the full working width. The 640 mm diameter rotor and the helical arrangement of the tines warrant a continuous crop flow, high throughputs and superior conditioning.  |

Firm grip on the crop: The V-tines are made from hardened steel and mount at a steep angle, treating the forage intensively and powerfully. The tines pivot to avoid foreign objects, yet their forward movement is restricted to increase the service life of the bolts. |

Nothing is left uncut: The arms on the side mowers telescope to provide the best possible overlapping with the front mower for a perfect cut.

|

Easy operation: The user-friendly control units on EasyCut B 750, B 870, B 890, B 970 und B 1000 allow operators to select transport position, headland and work position by flicking the rocker switches and control each mower separately.  |

|

Dialling in: A dial on the EasyCut B 870 CV Collect control box sets the belt speed infinitely variably. The belt stops moving the moment it is raised out of work.  |

|

Straightforward: The standard control unit on EasyCut B 1000 CV and CV Collect allows operators to adjust the mower suspension from a dial and to preselect a function which is then executed by a remote spool.  |

Thanks to its ISOBUS certification, the B 1000 can be operated from various tractor terminals. No further devices are necessary to operate the machine – for maximum operator comfort. |

|

EasyCut B 1000 CV · B 1000 CR Accurate overlaps

|

| The hydraulic sideshift feature on the side mowers eliminates any striping and maximizes efficiency productivity. The feature is standard specification. Cutting straight lines, the machine operates at the maximum width and minimum overlap, whereas larger overlaps and a narrow work width is selected when cutting curved lines. As you operate on the slope, simply retrieve a stored sideshift range to the right or left and avoid drifting and striping. |

Hydraulic control: Double-acting rams inside the mower arms extend and retract the arms on the move to vary the degree of overlap. |

Flexible: The ISOBUS terminal allows operators to move the rear mowers hydraulically by up to 40 cm in and out, either in sync. or independently. In addition, the standard-fi t terminal adjusts the work width simultaneously on both sides. |

| Name | Link |

| Brochure PDF | Download |

Tel:

Tel:  22 Callaghan Road, Lindsay, ON K9V 4R4

22 Callaghan Road, Lindsay, ON K9V 4R4

The robust combination combines state-of-the-art mower technology and offers working widths of 7.46 m to 9.70 m for productivity. The mowers not only offer light pulling and high acreages but also superior functionality and perfect cuts.

The robust combination combines state-of-the-art mower technology and offers working widths of 7.46 m to 9.70 m for productivity. The mowers not only offer light pulling and high acreages but also superior functionality and perfect cuts.