Today's HoursThursday 8:30AM - 5:00PM

Today's HoursThursday 8:30AM - 5:00PM

| Monday | 8:30AM - 5:00PM |

| Tuesday | 8:30AM - 5:00PM |

| Wednesday | 8:30AM - 5:00PM |

| Thursday | 8:30AM - 5:00PM |

| friday | 8:30AM - 5:00PM |

| Saturday | 8:30AM - noon |

| Sunday | Closed |

New Equipment

ID # 34914840

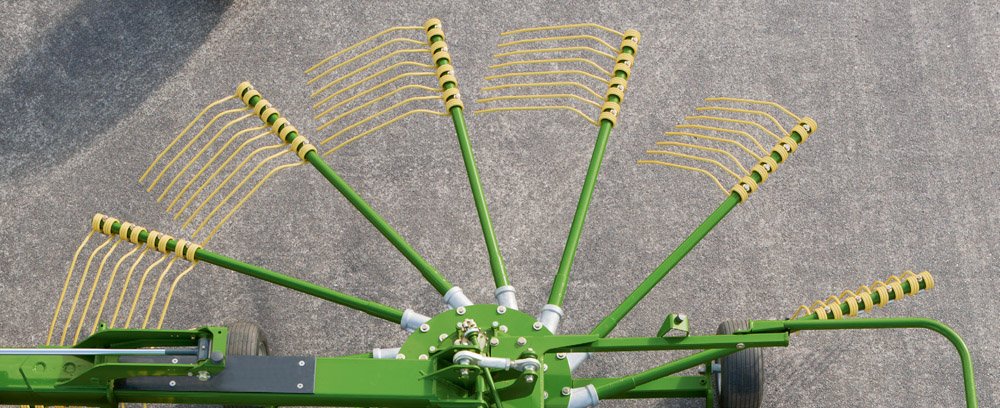

Krone Six-Rotor Rake

Call for Price

Overview

Specifications

the tine arms

easy operation

the jet effect

krone lift tines

the running gear

the cardanic rotor suspension

heavy-duty and maintenance-free

variable working and swathing widths

Videos

|

Swadro 2000

|

Model

Six-Rotor Rake

Category Name

Agriculture

Sale Type

New

Manufacturer

Krone

The Tine Arms

|

Stable running and tidy windrowing

|

Tine arms and tines: The tine arms are thick-walled and large in diameter. 10.5 mm (0.4") double tines that wind around the arms in three massive spring coils offering outstanding flexibility and longevity. Each tine arm carries four double tines. |

| Each tine arm is easily removed: Simply undo two bolts to remove the entire arm complete with bearing and roller. |

Sturdy foldback mechanism: Gap-free and hard-wearing functionality comes from a holder that is made from hardened steel and has a pivoting joint that is loaded by a Belleville spring on the models with multiple rotors. |

Easy Operation

| The operator uses the DS 500 terminal with backlit display screen to enter the rotor height, work width and windrowing width and activate the sequential lift-out and lowering actions. This terminal provides auto height control for all rotors on Swadro 2000 Plus after setting the height of one rotor. An optional joystick is available to offer even more convenient operation. |

| The CCI 800 terminal is ISOBUS-compatible, which means it can be fitted to most ISOBUS machinery irrespective of the make. This terminal is also available with an optional joystick. |

| Detecting raked areas and raising the rotors to avoid raking one patch twice, the automatic SectionControl feature is a great help for operators when swathing wedges and awkward areas. |

The Jet Effect

| The KRONE Jet Effect prevents the tines from damaging the sward on the headland and ensures the crop stays clean. As the bogies are lowered into work, the rear wheels touch down first before the leading wheels follow. Vice versa, as the rotors lift out it is the leading wheels that lift out first and the rear wheels that follow. This is identical with the take-off and touch-down phases observed with airplanes. |

KRONE Lift Tines

|

Clean windrows, better feed

|

| Setting the tines to an optimum position: The special Lift tines perform better, because their ends maintain a steep angle even in heavy crop and lift it more easily, which leads to more uniform windrows. As a result, the machine can work at a faster pace and still deliver consistently well shaped windrows. |

| No crop contamination: Thanks to their excellent performance, the Lift tines can work at a greater ground clearance than traditional tines. And thus reduce the risk of crop contamination as well as tine wear. |

The Running Gear

|

Great stability and excellent tracking

|

| Wide track width and quiet running: It is the extra wide tracking width of the running gear that absorbs the forces that are generated by the rotors and keeps them level and stable in undulating terrain. |

The Cardanic Rotor Suspension

|

Great flexibility and cleanest rakes

|

| The cardanic rotor suspension: The rotors pivot in and across the direction of travel to give optimum adaptation to undulating ground. A cardanic joint on the arm with two elongated holes prevents the tines from being pressed into the ground or from being left suspended in the air, thereby avoiding crop contamination as well as throwing the grass about. |

| The central suspension: The rotors suspend centrally across the direction of travel which allows them to produce consistent and high-quality windrows. The special suspension ensures they always stay level as they lift and lower on the headland. In addition, the machine’s weight is distributed uniformly on all wheels of the running gear as it travels down the field. |

Heavy-duty And Maintenance-free

|

| Permanently lubricated and maintenance-free. The enclosed bevel gearboxes and the tine arm rollers are permanently lubricated for optimum care and attention. So, operators need not bother to lube a single component on the rotor. |

| Boosting the productivity of the entire harvest chain is no problem for KRONE Swadro. The steep cam track is made from hard-wearing materials and provides precision guidance for the tines. A small track diameter in combination with massive cams make for quiet running, reduce wear and lead to well-shaped swaths. DuraMax cam track – maximum efficiency and maintenance-free components. Swadro is fun to use. |

Variable Working And Swathing Widths

| The variable work width: The work width is adapted to the capacity of the following harvester by moving the arms hydraulically into the proper position, thereby varying the working width from 10 m (32'10") to 19 m (62'4"). The two arms are synchronized by the sliding carriage as they move into position. |

| The flexible windrowing width: An optimal windrow width boosts the overall harvesting efficiency. The width of a windrow is altered by telescoping the rear arms hydraulically, which adjusts the distance between the two rotors at the rear. The telescoping arms adjust to widths between 1.80 m (5'11") and 3 m (9'10"). |

| The rotors lift out of work: They can lift/lower individually, sequentially or simultaneously. A hydraulic sequence control system is a particular boon for easy operation. Furthermore, a GPS based SectionControl feature is available as an option which lifts out individual rotors. |

| The tines on the four rotor tines operate at a higher speed than the units at the rear. The effect of differing rotor speeds is that the windrows are produced without roping. |

Model

Six-Rotor Rake

Category Name

Agriculture

Sale Type

New

Manufacturer

Krone

Quantity

0

Tel:

Tel:  22 Callaghan Road, Lindsay, ON K9V 4R4

22 Callaghan Road, Lindsay, ON K9V 4R4