Today's HoursThursday 8:30AM - 5:00PM

Today's HoursThursday 8:30AM - 5:00PM

| Monday | 8:30AM - 5:00PM |

| Tuesday | 8:30AM - 5:00PM |

| Wednesday | 8:30AM - 5:00PM |

| Thursday | 8:30AM - 5:00PM |

| friday | 8:30AM - 5:00PM |

| Saturday | 8:30AM - noon |

| Sunday | Closed |

New Equipment

Krone Fortima

|

The unit eliminates the risk of pushing up crop in uneven windrows. As a result, the machine operates at maximum pick-up and output levels while the crop is flowing smoothly and consistently through the machine. |

Massive augers feed the material from the sides to the middle of the machine, ensuring a smooth flow from the wide pick-up into the narrow bale chamber. |

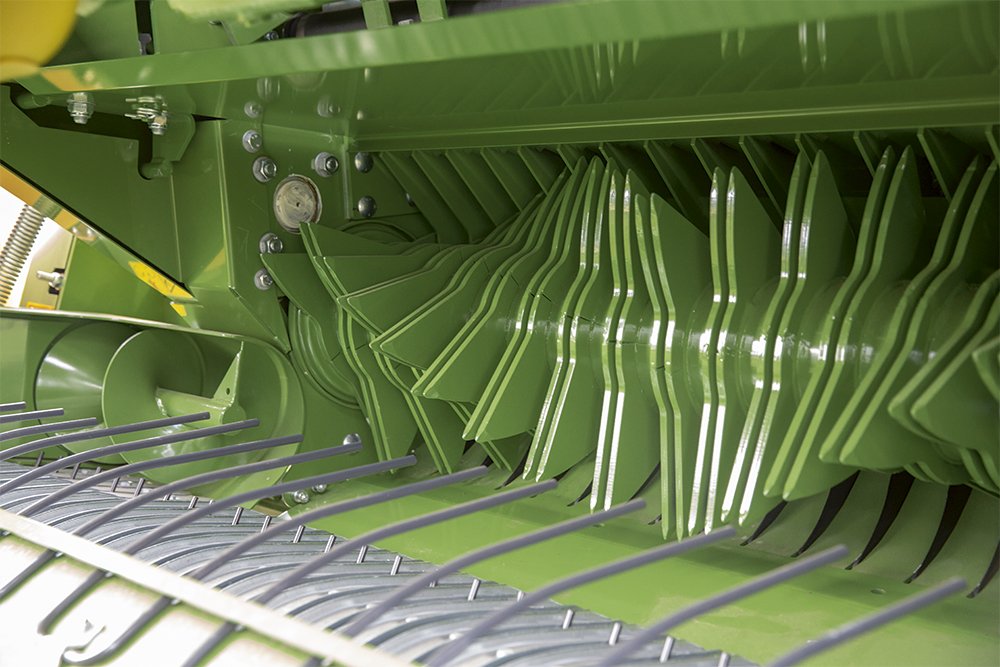

Boasting five rows of tines spaced 55 mm (2") apart, EasyFlow picks up even the short stems. The deflector plates are galvanized for ultimate durability. |

The EasyFlow pick-up forms a compact unit that comprises either a feed rotor or a cutting rotor. The clearance between rotor and baling chamber was increased and the rotor was arranged right behind the pick-up itself to increase the intake capacity and ensure a consistent flow even in short stems. |

Up to 17 blades in the KRONE MultiCut rotor cutting system deliver short chops that make for quick payback on your investment thanks to higher bale densities, enhanced silage quality as well as easier and faster bale break-up on the feeding floor. Short straw chops absorb liquids more readily, spread more easily. |

A maximum of 17 blades are narrowly spaced at 64 mm (2.5") to produce bales that are easy to break up and spread. The blades are arranged in one row for an excellent quality of cut. |

The automatic ‘Non-Stop’ auto-reset system and the hydraulic 0-blade selection system are standard specification. The hydraulic 0-blade selection is used to remove potential blockages from the feed channel. |

The double tines pull the crops consistently through the blades. The clearance between the blades and the double tines is very narrow so the crop cannot escape and the cuts are clean and precise. |

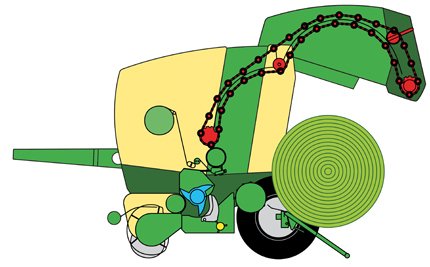

Round balers harvest straw, hay and wilted silage around the world in a wide variety of conditions that require full operational reliability. The chain-and-slat elevators respond to these requirements and operate dependably in all these conditions. |

The KRONE chain-and-slat elevator is gentle on the crop. By meshing with the material, it ensures effective bale roll and highest densities. |

The heavy-duty chain-and-slat elevator runs on massive guide and drive rollers. The use of more chain links distributes the load more evenly and the use of massive rollers increases the angle at which the chains change direction, reducing the wear on the elevator, increasing its capacity and leading to smooth running. Individual chain links are easy to replace as required. |

Take advantage of the headstart you get from the fixed-chamber round balers Fortima F 1250 and F 1600 with and without MultiCut cutting system. Boasting a host of unique features - the camless pick-up, the chain-and-slat elevator, the simple design, top durability and low maintenance – these balers mean quick payback on your investment. |

The chain-and-slat elevator adds layer after layer to the rolling bale, forming tight and well-shaped round bales. The chain-and-slat elevator scores especially on its superior feeding ability. Rolling starts earlier and so the baling cycle finishes earlier as well. The elevator also creates a firmer core and packs more weight and density into each bale, which translates into higher quality silage and better exploitation of truck capacities. |

The ejector throws the bale clear of the rear door and also serves as a tray that collects the bale. The benefit? You can start the next cycle while the rear door is still closing. |

The variable chamber round balers Fortima V 1500 and V 1800 meet all requirements. One machine produces 1.00 m to 1.50 m (3'3" - 4'11") or 1.00 to 1.80 m (3'3" - 5'11") diameter bales to cater for grass silage applications where smaller bale sizes are preferred as well as applications in hay and straw where larger bales are typical. |

Fortima is equipped with two chain-and-slat elevators, one operating at the front end and the other at the rear to develop high baling pressures and produce perfectly shaped bales. |

As more material enters the bale chamber, the two chain elevators press layer by layer to form tight and well-shaped round bales. The slats mesh with the crop to provide positive bale rotation at any stage of the baling cycle. The baling pressure is supplied by a hydraulic ram that actuates the tensioning arms at the front and rear ends. As soon as the bale has reached its preset diameter, twine or net wrapping is triggered. As a last step, the tailgate opens and the bale is ejected. |

We at KRONE understand the needs of farmers. Providing high bale densities, KRONE balers are extremely robust, uncluttered and perfectly specified. Last but not least, they offer superior operational reliability. |

Small diameters are typical in silage making, because small bales are easier to handle, break up and feed. The 1.00 - 1.30 m (3'3" - 4'3") diameter bales produced by Fortima V 1500 suit most wrappers perfectly. |

Large-diameter bales are often preferred in straw and hay as they offer better efficiency, save on wrapping material and reduce labour costs. |

Depending on the level of specified on-board electronics (Medium or Comfort), the Fortima balers can take either the double twine tying system or the faster quad twine system. Either option ensures generous string overlap on the bale and multiple ties along the edge so the bale keeps its shape. |

A coned pulley controls the number of twine layers applied per cycle. Two guide blocks are used to distribute the four threads uniformly across the full width of the chamber. As the ball starts to roll, the rubber roller and the pressure roller start feeding the twine into the chamber where they are picked up by the rolling bale. |

Four threads ( 1 - 4 ) tie the bale a number of times, which allows applying extra wraps along the edges, depending on the settings. Four threads warrant well-shaped bales that will not lose shape as they are handled several times over. |

Fortima’s net wrapping system is straightforward by design and offers superior functionality. Net wrapping is faster than twine wrapping and increases output rates. The net wrap system accepts rolls with a total net length of up to 3,600 m (11,811 ft). |

The large storage compartment holds three net rolls and protects them from rain. The rolls may provide up to 3,600 m (11,811 ft) of netting and are secured by a retainer. |

Replacing the net roll is convenient and safe, because the operator can stand upright when reloading. To replace an empty net roll, simply swing out the dispenser arm and slide the fresh roll onto it. Then the net is fed into the net wrap system. |

Not only is Fortima designed for highest densities and outputs but it also stands out for an uncluttered layout and easy access to all service points. A grease bank and the automatic chain lubricator minimize service and maintenance. |

To avoid downtime due to contaminated oil, the variable chamber Fortima features an oil strainer with a visual indicator to ensure optimum functionality and peace of mind. |

All ‘hidden’ lubrication points are grouped in easy-access lubrication banks, making service and maintenance less time-consuming and more convenient. |

Special conditions require special equipment. To meet all our customers' requirements, Fortima is available with a wide range of running gear. Choose from standard and tandem setups, braked and unbraked versions as well as air and hydraulic brakes (export version). |

The standard axle is available with 11.5/80-15.3/10 PR to 500/50-17/10 PR sized tyres. Large flotation tyres reduce the risk of ground compaction and prevent rutting. |

The optional tandem axle gives soft, quiet and safe running. The choice of tyres available ranges from 11.5/80-15.3/10 PR to 19.0/45-17/10 PR. |

An air brake system is available as optional specification for Fortima V 1500. Export models can be specified with hydraulic brakes. |

Tel:

Tel:  22 Callaghan Road, Lindsay, ON K9V 4R4

22 Callaghan Road, Lindsay, ON K9V 4R4